- Home

- Product

- Liquid packing machine

- Cheap Price 1 kg Coconut Milk Juice Packaging Machine

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

Cheap Price 1 kg Coconut Milk Juice Packaging Machine

The model of the packaging machine in the video is SK-L420-Y vertical automatic liquid packaging machine. The weight of the packaging in the video is 1 kg of coconut juice, and the packaging speed is about 15-20 bags. The packaging machine is made of all 304 stainless steel, and the liquid storage hopper Cooperate with rotor pump liquid metering device for metering use.

Liquid packingm machine's companent:

1) Mian packing machine 2) Liquid pump

Some detaied pcitures of Liquid packing machine

material stroage hopper

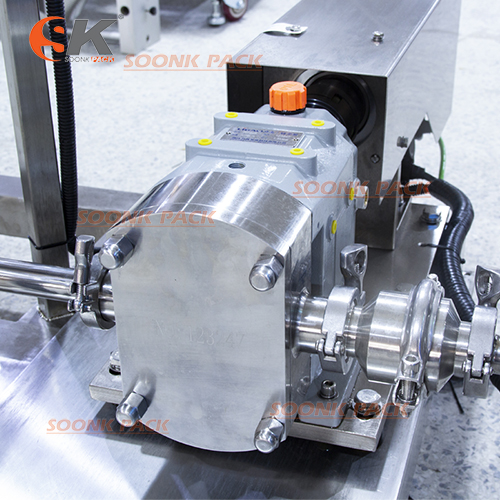

Rotary pump metering device

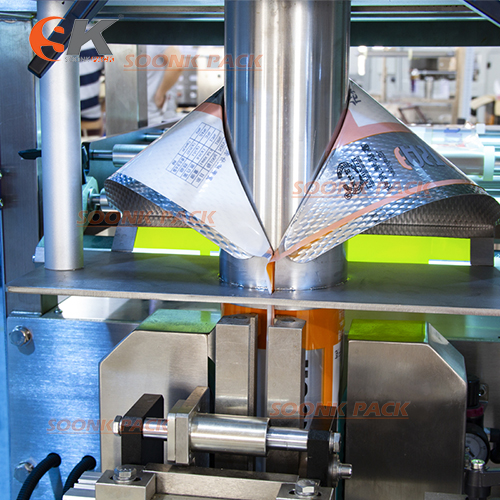

Collar type bag former

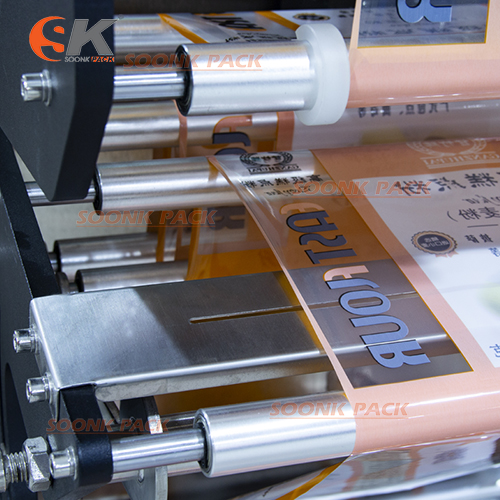

Film release device

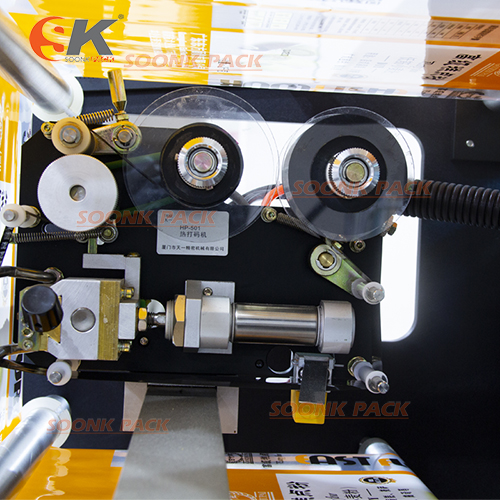

Date Printer device

Vertical sealing device

Horizontal sealing device

Computer touch screen

Material storage device: It is made of 304 food grade stainless steel, and stores related packaging materials with large storage capacity.

Rotary pump metering device: It adopts external dynamic and static ring mechanical seals, which can be directly washed with water, is resistant to high pressure, is not easy to wear, and has no leakage; small size, large flow, high head pressure, suitable for long-distance and high resistance quantitative transportation.

Film release device: The film unloading device of the packaging machine adopts an external film putting mechanism, which is convenient and quick to replace the packaging film

Date Printer device: The packaging machine is equipped with a coding machine device, which automatically prints the production date and can print three lines. The font size is: 2*4mm.

Horizontal sealing device: Double-sided heat-sealing cutting knife is used, so that the horizontal sealing can be quickly heated and can cut perfect packaging bags.

Horizontal sealing device: the packaging film is heat-sealed on both sides; the sealing can be quickly and evenly heated, and the back of the packaged product can be sealed and sealed longitudinally, so that the back-seal can be heat-sealed firmly.

Collar type bag former: This machine adopts a specific lapel bag former, which makes the film stretch run stably and improves efficiency; it is not easy to run the film and the forming is more beautiful.

Computer screen control: The electronic scale and the packaging host are independent computer touch screen control systems, using Chinese and English languages, the program is easy to update, the operation program is simple and easy to understand, intuitive and efficient.

Product introduction:

Liquid packaging machine is a liquid packaging machine with high packaging efficiency and good edge sealing effect. It is mainly used for packaging liquid seasonings. It can accurately measure and weigh the packed materials, reducing the subsequent weighing steps. , The equipment uses a multi-layer seal design to ensure that there is no dripping after filling.

Introduction of milk packing machine :

This machine is widely used in milk, soy milk, various beverages, soy sauce, vinegar, rice wine and other liquids. After ultraviolet sterilization, bag forming, date printing, quantitative filling, sealing and cutting, the product is beautiful and reliable. The whole machine adopts stainless steel structure to ensure that it meets international health standards. It can use color printing composite film and photoelectric detection to ensure complete patterns.

Performance characteristics of 1 kg vertical automatic juice milk packaging machinery and equipment:

1. The main machine of the packaging machine is made of high-quality 304 stainless steel. 304 stainless steel has the characteristics of anti-rust and corrosion resistance. When packaging, ensure that the materials are clean and hygienic;

2. The servo double film pulling system is used to pull the film to ensure that the packaging film is conveyed smoothly and neatly, and the bag is flat;

3. Imported brand air cylinders are used to ensure good sealing performance of the bag and clear sealing lines, prevent air leakage of the packaging bag, and reduce the rejection rate;

4. The packaging machine is equipped with a color code photoelectric eye and a date printing device;

5. The horizontal and vertical seals adopt an independent temperature control meter, which can control the temperature of the horizontal and vertical seals separately;

6. There are multiple language operating system options;

7. Using an external film placement mechanism, it is faster to replace the packaging film;

8. Packing can automatically complete all the processes of feeding, metering, filling and bag making, date printing, and product output at one time;

9. The film unwinding device adopts the film unwinding motor with brake function, so that the packaging film can be parked freely without wasting the roll material. The film release position uses two thick steel fixing rings to fix the packaging film, so there is no worry about the deviation of the coil.

Operating procedures:

1. Before turning on the automatic liquid packaging machine, check whether there is any abnormality around the machine.

2. When the machine is running, it is strictly forbidden to approach or touch the running parts with your body, hands and head.

3. When the machine is running, it is strictly forbidden to extend hands and tools into the sealing knife seat.

4. When the machine is working normally, it is strictly forbidden to switch the operation process button frequently, and it is strictly forbidden to change the parameter preset value frequently.

5. Fast and long-term operation is strictly prohibited.

6. It is strictly forbidden for two people to operate the various switch buttons and mechanisms of the process machine at the same time; the power should be cut off during maintenance and maintenance; when multiple people are debugging and repairing the machine at the same time, pay special attention to communication and signal to avoid accidents caused by incoordination .

7. When checking and repairing electrical control circuits, it is strictly forbidden to work with electricity! Be sure to disconnect the power supply! It must be carried out by electrical professionals. The equipment is automatically locked by the program and cannot be modified privately.

8. When the operating process personnel are unable to clear their minds due to drinking or fatigue, it is strictly forbidden to perform the operating process, debugging or maintenance work; other personnel without training or qualifications are not allowed to operate the process machine.

Suitable for packaging machines of various liquids such as detergent and sauce products, rice wine, soy sauce, chili oil, jam, fruit juice, beverages, white wine, water, instant noodle seasoning water, cold skin seasoning water, vinegar, shampoo, tomato sauce, milk , Coconut milk and other products with good liquidit

The bag type of the packaging machine in this video is a back-seal bag type. The picture below is a physical display.

|

Product name |

SK-L420-Y vertical liquid packing machine |

|

Air consumption consumption |

0.65mpa,2.5m3/min. |

|

Packaging film width |

420mm |

|

Bag length |

80-300mm |

|

Bag width |

80-200 mm |

|

Max outer diameter of coil |

Max.360mm |

|

Packing speed |

10-35 bags/min |

|

Packaging film thickness |

0.04-0.08mm |

|

Power Specifications |

220V.50/60Hz.3 Kw |

|

Dimensions |

(L)1450*(W)1000*(H)1600mm |

|

Net weight |

450kg |

|

Gross Weight |

500kg |

|

Packaging materials |

Composite film |

What is the cause of the inaccurate metering of the liquid pump of the vertical automatic liquid packaging machine?

In daily life, you can see bagged liquid products everywhere, such as bagged soy sauce, bagged red oil, bagged chili sauce, bagged ketchup, bagged rice wine, bagged water, bagged milk, etc. Many are packaged in bags. Packed in bags for easy carrying.

For these bagged liquid products, we generally use a vertical automatic liquid packaging machine for packaging, and use a vertical automatic liquid packaging machine to replace manual packaging. This ensures that the liquid products are clean and hygienic during the packaging process and reduces labor costs. And the cost can also improve the efficiency of packaging and shorten the delivery cycle.

The measurement link of the vertical automatic liquid packaging machine is to use the liquid pump for measurement. When adjusting the weight of the vertical automatic liquid packaging machine, we need to adjust the liquid pump to achieve the corresponding effect, but if the liquid pump is not accurate , What caused it?

1. Whether the model of the liquid pump and metering pump matches the metering requirements;

2. Measure whether the cylinder formation is in place;

3. Whether a check valve is installed at the inlet of liquid materials with good fluidity;

4. Whether the action of the unloading cylinder matches the action of the metering cylinder;

5. Whether the discharge port of the liquid pump is blocked quickly and whether there is material leakage.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us