- Home

- Product

- Powder packing machine

- Fully Automatic Seasoning Powder Packaging Machine

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

Fully Automatic Seasoning Powder Packaging Machine

The powder packaging machine in the video is mainly composed of a material storage hopper, a scraper feeder, a powder head metering device, and a 520 packaging machine host. The packaging film uses aluminum foil bags, and the bag type adopts a back-seal sealing method. According to conventional powder materials We will use a screw feeder for feeding, but for this combination, we use a scraper feeder for feeding. Compared with the screw feeder, the scraper feeder is convenient and quick to clean and directly flip the plate. Open it to clean up.

Powder packing machine's companent:

1) Mian packing machine 2) Auger fille 3) Scraper feeder 4) Finished bag conveyor

Some detaied pcitures of Liquid packing machine

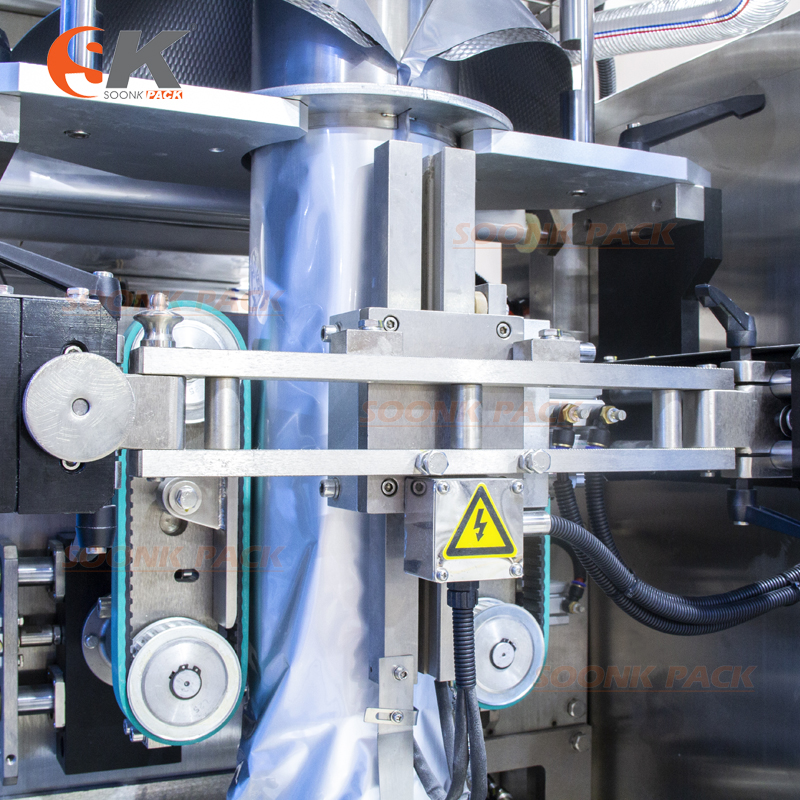

Auger filler device

Bag former

.

.

Vertical sealing device

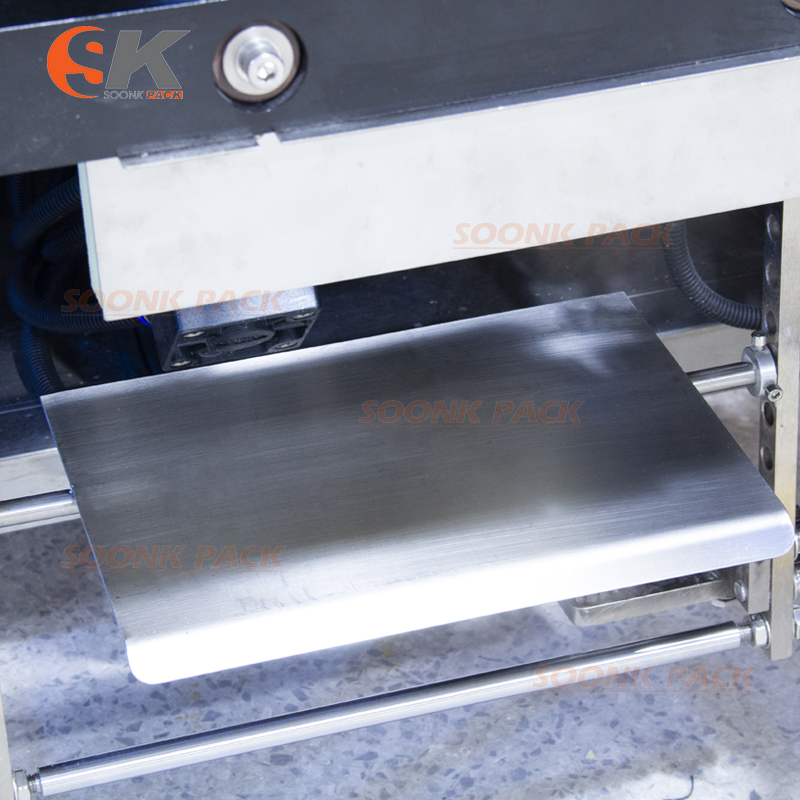

Horizontal sealing device

Supporting material device

Touch screen device, temperature control meter

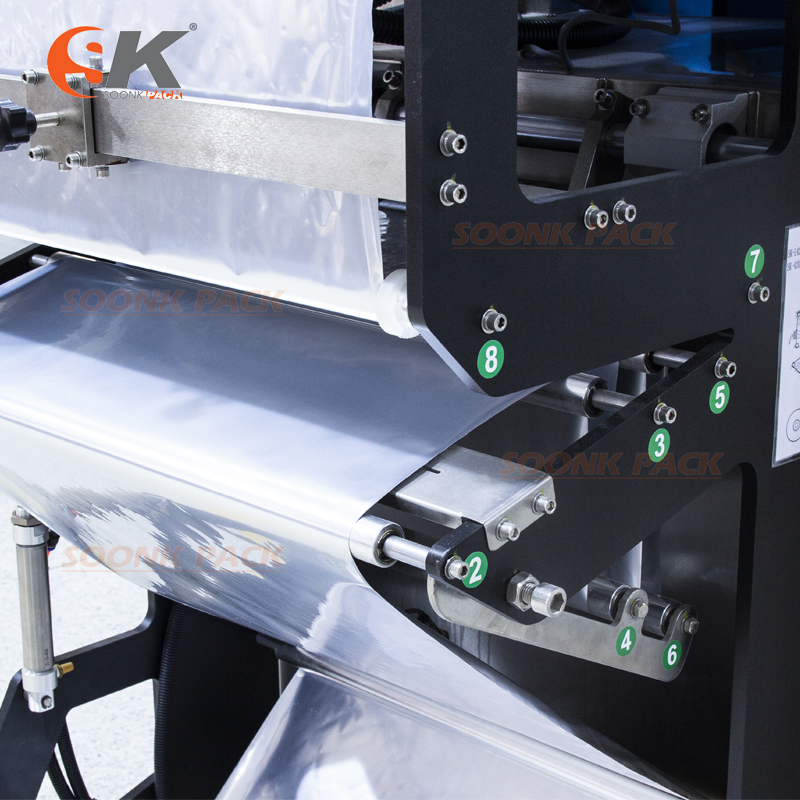

Film unwinding mechanism

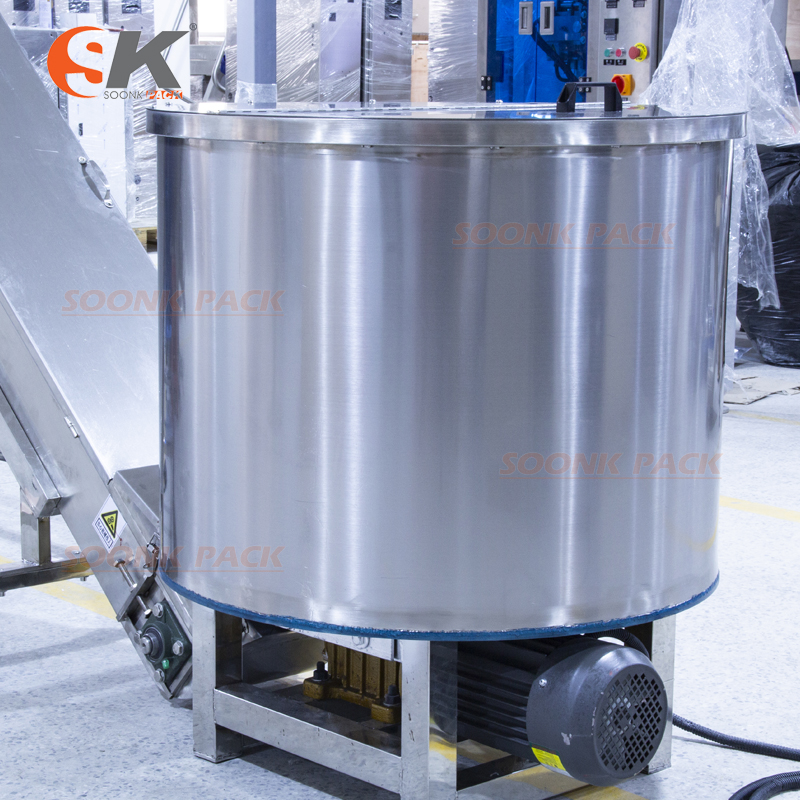

Storage hopper device

Scraper feeder

Auger filler device: powder metering device is made of high-quality 304 stainless steel, with inclined screw metering device, which is accurate in weighing and measuring. The weighing and measuring speed is fast.

Bag former :The bag former is made of stainless steel and has a long service life. The adjustment of the shaper can be adjusted through the touch screen, the operation is simple and convenient.

Scraper feeder:The scraper is used for feeding. The scraper is not airtight. If sanitation

Film unwinding mechanism: The external packaging film unwinding device is adopted, and the multi-link film reeling shaft coordinates the film transportation, and the film rolls more smoothly; the film conveying device adopts machining, and the details are processed accurately.

Supporting material device: For heavy bags of mate-rials, add a supporting device to avoid pleating or poor sealing.

Storage hopper device :The material is made of stainless steel with a large volume, which can store a large amount of materials.

Horizontal sealing device: the horizontal sealing device of packaging machine has the same smooth surface treatment without hand stroke, and is equipped with fillet device.

Vertical sealing device: the vertical sealing device of packing machine. The surface of the longitudinal sealing rod is smooth without scratching..

Touch screen device, temperature control meter: Use the man-machine interface touch screen, the touch screen is sensitive, and the relevant values can be adjusted arbitrarily, which is convenient and quick; the horizontal seal and the vertical seal use an independent temperature control meter, which can individually control the relevant temperature.

Product introduction:

This automatic powder packaging machine is the latest powder packaging machine series launched by our company. It is specially designed and manufactured for powder series powder and ultra-fine powder materials. It adopts intelligent numerical control system, microcomputer PLC control, and is equipped with high precision. Servo motor/stepping motor, stepping motor pulls the bag, the bag making length is consistent, the performance is stable and reliable; the filling mechanism adopts the stepping motor to drive the feeding screw to ensure the accuracy of measurement; the sealing and cutting are integrated, no need to adjust the knife to ensure the horizontal The sealing width is error-free; double-sided heating is very suitable for the chicken juice powder packaging bag composite film packaging material; it can be accurate that each packaging bag pattern is in the same position, and can automatically fix the length, position and speed, when there is no material or jam With automatic shutdown function, this fully automatic powder packaging machine has been favored by many chicken powder companies since it went on the market.

Introduction of powder packaging machine:

Suitable for automatic bag packaging machine products for powder products. General machines can automatically complete all tasks such as metering, filling, sealing and cutting. The volumetric method is mostly used for measurement, and some models are also equipped with a reliable photoelectric detection system. When packaging materials with photoelectric marks are used, a complete trademark pattern can be obtained. The powder packaging machine is suitable for small bag packaging of medicine, food, chemical industry, pesticide, etc. It is suitable for manufacturers of powdered medicines, sugar, coffee, fruit jelly, tea, monosodium glutamate, salt, seeds, desiccants, etc.

use:

The powder packaging machine is suitable for powder packaging of medicines, milk tea, milk powder, seasonings, etc. It can automatically complete the work of measuring, bagging, filling, sealing, sewing, conveying, etc. for powdery or granular materials that are easy to flow or have extremely poor fluidity, with high accuracy , High reliability, not easy to wear.

Performance characteristics:

1. The auger filler metering device is made of high-quality 304 stainless steel, and the straight screw metering device is accurate in weighing and measuring. The weighing and measuring speed is fast.

2. Adopt an external packaging film release device, multi-link film reel axis coordinated film transport, the film roll is more smooth; the film transport device is machined, and the details are processed accurately.

3. It uses automatic thermal coding instead of ink printing to print clear characters efficiently, 20-120 times per minute, easy to use, and convenient to maintain.

4. Using the human-machine interface touch screen, the touch screen is sensitive, and the relevant values can be adjusted arbitrarily, which is convenient and quick; the horizontal and vertical seals use an independent temperature control meter, which can individually control the relevant temperature.

5. The electrical control parts of the packaging are arranged neatly and orderly, and the relevant electrical control accessories can be found quickly and effectively in the event of a failure.

6. The packaging machine adopts a double-stretching film system to ensure that the packaging film is stable during the conveying process and the bag is stable.

7. A constant temperature heat-sealing cutter is used to seal the front and rear ends of the packaged product, and an exhaust device or a gusset device can be installed as needed.

8. This machine adopts a specific lapel-type bag forming device, which makes the film stretch stable and improves efficiency; it is not easy to run and the film is more beautiful.

9. For heavy bags of materials, add a supporting device to avoid pleating or poor sealing.

10. The scraper feeder is used for feeding. The scraper feeder is not airtight. If sanitation is required, it can be cleaned by opening the panel, which is convenient and simple.

11. The material is made of stainless steel to make a large volume, which can store a larger amount of materials.

Performance advantages of automatic powder packaging machine:

1. Stepping motor pulls film, screen adjustment parameters, easy to operate.

2. The expansion function is strong, can connect the bag device, the inflation device, meet the needs of different products.

3. Bag making, filling, measuring, sealing, date printing, and product output are completed at one time.

Operation method of powder packaging machine:

1. Install the machine: first install the machine and the packaging film, install the packaging paper on the bracket, and try to make the edge of the packaging paper and the gap between the support frame vertical and parallel.

2. Power on: After installing the machine and placing it flat, plug in the power and turn on the power switch and wait for the machine to work. The power plug must be connected to a plug with a grounding wire.

3. Setting parameters: set the length of the packaging bag, temperature parameters and the number of grams of blanking.

4. Pour the materials: Pour the materials into the hopper and press start to work.

5. Automatic packaging: the machine automatically weighs, blanks, seals, and cuts into bags, and the packaging is formed at one time.

The automatic quantitative powder powder packaging machine is suitable for packaging powder powder products with good fluidity, such as seasoning powder, milk powder, soybean powder, tea powder, pepper, starch, flour, medicinal powder, arrowroot powder, tapioca powder, tempura Powder, Orleans roasted wing powder, talcum powder, coffee powder, washing powder, color masterbatch and other powder powder products.

Generally, the standard bag type of the automatic quantitative powder packaging machine is a back-seal bag type, which can be made into a gusset bag type or a four-side hot bag type according to the requirements of the customer.

|

Product name |

SK-L520FT Fully Automatic Seasoning Powder Packaging Machine |

|

Air consumption consumption |

0.65mpa,2.5m3/min. |

|

Packaging film width |

520mm |

|

Bag length |

80-350m |

|

Bag width |

100-250 mm |

|

Max outer diameter of coil |

Max.360mm |

|

Packing speed |

10-55 bags/min |

|

Packaging film thickness |

0.04-0.08mm |

|

Power Specifications |

220V.50/60Hz.3 Kw |

|

Dimensions |

(L)1430*(W)1200*(H)1700mm |

|

Net weight |

600kg |

|

Gross Weight |

650kg |

|

Packaging materials |

Composite film |

Operating rules of automatic packaging machine

We all know that every machine and equipment product has its certain standard operating procedures. Naturally, automatic packaging machines are no exception and require irregular inspections and maintenance. Foshan Soonkpack Packaging Machinery Co., Ltd. is a professional manufacturer of fully automatic A series of large packaging machine manufacturers such as packaging machines, vertical packaging machines, food packaging machines, granular packaging machines, liquid packaging machines, daily products, etc., with 13 years of experience in the packaging industry, can provide customers with a full range of solutions. The following are introduced Here are the 8 operating procedures of the automatic packaging machine.

Automatic packaging machine operating procedures

1. Before starting the machine, check whether the compressed air pressure meets the requirements (above 0.6bar), and check whether the main components are intact, such as heating belts, scissors, and various parts of the trolley. Check whether there are other people around the machine together to ensure safety after the machine is turned on.

2, the feeding system and the measuring machine are cleaned before production to ensure the hygiene of the product.

3. Close the main power air switch, turn on the power to start, set and check the temperature of each temperature controller, and put on the film.

4. First adjust the bag making and check the coding effect, and open the feeding system to supply materials together. When the materials meet the requirements, first open the bag making mechanism and check the vacuum degree and heat sealing quality of the vacuum box drawn by the vacuum box together, that is, bag making After reaching the requirements, start material filling and production.

5. During the production process, check the quality of the product at any time, such as whether the basic requirements of the product such as cossette in the mouth, vacuum degree, heat sealing line, wrinkle, weight, etc., are qualified, and adjust at any time if there is any problem.

6. The operator is not allowed to adjust some operating parameters of the machine at will, such as the number of operations, servo and frequency conversion parameters. If adjustment is required, it is necessary to report the section length, and the relevant repairers or technicians will adjust it together; during production, according to In reality, the operator can properly adjust the temperature and some phase angle parameters of each temperature controller, but it is necessary to notify the team leader and section chief first to ensure that the various parameters of the equipment operation are controlled during the entire production process to ensure the stability of the equipment Operation to ensure normal production and product quality.

7. If there is a problem with the equipment or the quality of the product is unqualified during production, the machine should be shut down immediately to deal with the problem. It is forbidden to deal with problems during the operation of the machine to prevent the occurrence of safety accidents. If you can’t handle the big problem yourself, immediately notify the team leader and let the repairer handle it together, and hang up the safety warning sign "Inspection and repair, no power-on". It is necessary for the operator to deal with the problem together with the repairer, to solve the problem in a faster time, and to resume production.

8. During the operation, operators should always pay attention to the safety of themselves and others, especially the safety of heat-sealing knives, scissors, trolley parts, vacuum boxes, camshafts, measuring cup observation holes of measuring machines, mixing of measuring machines, conveyors, etc. And protection to prevent the occurrence of safety accidents.

9. The operator can only use clean fingers to touch the touch screen of the machine. It is forbidden to press or hit the touch screen with fingertips, nails, or other hard objects. Otherwise, the touch screen will be damaged due to improper operation.

10. When debugging the machine or adjusting the quality of bag making, the quality of opening the bag, the filling effect, the car show bag and the bag receiving, only manual switch can be used for debugging. The above debugging is prohibited when the machine is in operation, so as to avoid the occurrence of safety accidents. . When a relatively large fault requires debugging and processing, and when you want to open the cam box to adjust the cam or change the tension spring, it is necessary to hang the "under maintenance, no power-on" safety warning sign on the touch screen of the machine operation, and anyone can see it. If there are safety warning signs, do not turn on the machine at will, otherwise you will bear the consequences.

11. Every operator shall ensure the sanitation of the machine and the surrounding ground at any time, and clean up the shreds on the ground and on the machine in time. Roll film, cartons and other sundries shall not be placed around the machine, and plastic baskets of unqualified products and sundries shall be placed as standard. Keep the scene tidy.

12. Clean the floor products at any time, adhere to the sanitation of the platform, and pay attention to whether the conveyor belt is off-track at any time. If the conveyor is off-track, correct it immediately to avoid damage to the conveyor belt.

13. After the production of each shift, the operator must cut the bottom to clean the sanitation of the machine and equipment. During the cleaning process, it is forbidden to use large water or high-pressure water to flush the equipment (except for the special small water gun configured for each machine), pay attention to it together Protect the electrical parts. After cleaning, make sure that there is no accumulation of water on the machine and the ground before leaving.

14. Before leaving get off work every day, it is necessary to accurately count the consumption of each machine's film and the total consumption of the film on duty, and make statistics of the output value of a single machine and the total output value of the job together.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us