- Home

- Product

- Semi-automatic packing machine

- High Speed Spoon Knife Fork Toothpick Nipkin Culter Packaging Machine

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

High speed Spoon Knife Fork Toothpick Nipkin Culter Packaging Machine

The packaging machinery we saw in the video is mainly a combination of chain bucket conveyor and SK-L320 packaging host. In addition, customers can manually put the product into the chain bucket for packaging according to the product, or it can be fully automated by connecting the production line. The packaging material of this cutlery packaging machine is roll film, which is made into bags by packaging equipment.

Spoon Knife Fork Toothpick Nipkin Culter packing machine component:

1 ) Mian packing machine; 2 ) Chain bucket

Some detailed pictures of Spoon Knife Fork Toothpick Nipkin Culter packing machine

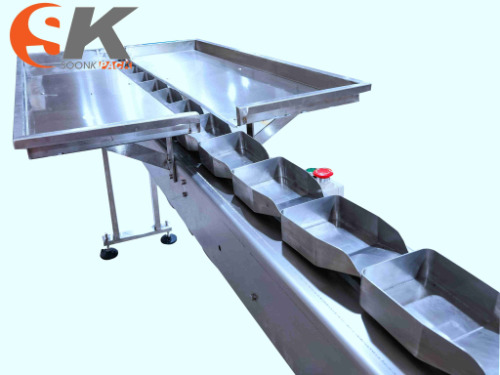

Chain bucket device

Date Printer device

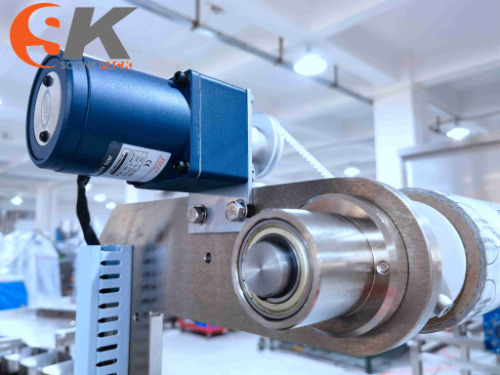

The film release device

Film transport device

Intelligent industrial-grade touch screen

Vertical sealing device

Horizontal sealing device

Electronic control part

Chain bucket device:

Manually put the product into the chain bucket, fast speed, simple structure。

The film release device :

It adopts a film release motor with brake function, so that the packaging film can be stopped freely without wasting the roll material. The film release position uses two thick steel fixing rings to fix the packaging film, so there is no worry about the deviation of the coil.

Date Printer device:

The packaging machine is equipped with a coding machine device, which automatically prints the production date and can print three lines. The font size is: 2*4mm

Film transport device:

The film transport device is made of high-quality materials, with smooth surface treatment, no scratching, no damage to the coil, flexible rotation of the film roller handling, suitable gaps, and the packaging coil does not run off, resulting in a perfect bag.

Intelligent industrial-grade touch screen:

High sensitivity,stable operation, easy to understand and easy to operate; two temperature control meters, independent control and stability, making beautiful bags.

Vertical sealing device:

The vertical sealing device of packing machine. The surface of the longitudinal sealing rod is smooth without scratching.

Horizontal sealing device:

The horizontal sealing rod adopts a movable flip cover, which is convenient for easy replacement of the heating tube when it fails.

Electronic control part:

The circuit is clear and easy to understand .

Product description:

Disposable knife, fork, and spoon tissue is an indispensable part of modern society. Whether it is breakfast, lunch, or dinner, they will choose disposable knives, forks, and spoons. Because many young people need to order takeaway, they need to use a knife, fork, and spoon. It's easy to get up, so it is loved by more people. This SK-L320 semi-automatic disposable knife, fork, spoon, and tissue packaging machine is a combination of a chain bucket conveyor and SK-L320 packaging host. In addition, customers can manually put the products into the chain bucket for packaging according to the products, or they can be fully automated by connecting the production line. The packaging material of this tableware packaging machine is roll film, which is made into bags by packaging equipment.

Knife, fork, spoon, and chain bucket semi-automatic packaging machine is a performance feature;

1) The main machine of packaging machine is the SK-L320 model, which is made of 304 stainless steel. The overall design is reasonable, generous, and not occupying a position;

2) Using stepper motor control to ensure smooth delivery of packaging film and smooth bagging;

3) Imported brand air cylinders are used to ensure good sealing of the bag and clear sealing lines, prevent air leakage of the packaging bag and reduce the waste rate;

4) It adopts PLC control, imported drivers, imported brand touch screen, man-machine interface, high degree of automation, simple operating procedures, and high touch screen sensitivity;

5) Multi-language operating system selection;

6) The chain bucket conveyor is used to transport materials, and the chain bucket can be customized according to the characteristics of the product, with strong plasticity.

Manually transport the material inside the chain bucket to the packaging machine through the chain bucket. Finally, seal and cut the bag at a high temperature. The machine has been modified to automatically complete the entire production process, including feeding, metering, filling and bag making, date printing, and product output.

The semi-automatic packaging machine is suitable for all kinds of fragile or difficult to measure materials, such as potato chips, shrimp chips, french fries, jelly, dumplings, glutinous rice balls, preserved fruits, candies, dry goods, fried food, hardware accessories, plastic accessories, toys, fruits and vegetables, various vermicelli, wet vermicelli, udon noodles, potato flour, etc

The bag types that can be selected for the chain bucket semi-automatic packaging machine are back seal, gusseted bag, back seal round hole, airplane hole, portable hole, etc.

|

Product name |

SK-L320 Spoon Knife Fork Toothpick Nipkin Culter Packaging Machine |

|

Air consumption consumption |

0.65mpa,2.5m3/min.6kg/cm2 |

|

Packaging film width |

320mm |

|

Bag length |

50-200mm |

|

Bag width |

30-150mm |

|

Max outer diameter of coil |

Max.360mm |

|

Packing speed |

15-60bags/min |

|

Packaging film thickness |

0.04-0.08mm |

|

Power Specifications |

220V.50/60Hz.2.4Kw |

|

Dimensions |

(L)1200*(W)820*(H)2100mm |

|

Packaging materials |

Composite film |

What is the reason why the conveyor chain bucket of the vertical semi-automatic chain bucket packaging machine does not work

A vertical semi-automatic chain-bucket packaging machine is a kind of vertical granule packaging machine. A vertical semi-automatic chain-bucket packaging machine is mainly used to pack granular materials. The chain-bucket semi-automatic packaging machine is manually weighed and weighed. Put it in the chain bucket and transport it to the lower hopper for packaging.

Generally, there are three situations in which vertical semi-automatic chain-bucket packaging machines are used for packaging. One is because the company has limited funds for the use of automation, the other is that the materials are not suitable for weighing using automated weighing equipment, and the third is that the packaging needs to be invested. Different types of materials, such as prize cards, etc., can be packaged using a vertical semi-automatic chain-bucket packaging machine in these situations.

When manual labor uses the vertical semi-automatic chain bucket packaging machine to package products, the conveyor chain bucket may not work due to misoperation or failure of product accessories. So what causes the conveyor chain bucket of the vertical semi-automatic chain bucket packaging machine to not work?

1. Whether the clutch fork of the conveyor chain bucket of the vertical semi-automatic chain bucket packaging machine is in the closed state;

2. Whether the fastening screws and flat keys of the transmission position of the equipment are installed properly;

3. Check whether the motors of the conveyor chain bucket of the machine are malfunctioning, whether the gearbox is lack oil or lubrication, etc.;

4. Whether the inverter is damaged or not working;

5. Check the circuit of the control electric box of the vertical semi-automatic chain bucket packaging machine and the related components and the positioning electric eye for failure.

The common faults and corresponding maintenance solutions of the 8-point vertical packaging machine are as follows:

|

Fault type |

Reason |

Corresponding maintenance solutions |

|

The machine does not work after touching the "on" button in the production operation menu. |

1. Check whether the emergency stop switch is reset 2. Inverter and servo controller display RC (in alarm state) |

1. Reset the emergency stop switch 2. Turn off the main power and turn it on again after 20 seconds |

|

Leakage switch tripped |

Leakage of heating pipes and other electrical appliances |

Check each electrical appliance one by one |

|

The sealing roller is not hot |

1. The power failure protector trips 2. The heating tube burns out 3. The temperature control meter is damaged |

1. Check and eliminate the short circuit, then reclose 2. Replace the heating tube 3. Replace the temperature control meter |

|

The temperature control meter digits beating repeatedly |

Loose or damaged thermocouple |

Tighten or replace the thermocouple |

|

The temperature is normal when the machine is stopped, and the temperature keeps dropping after the machine is started |

1. The ambient voltage is low, causing the power of the heating tube to decrease 2. The power of the heating tube is too small |

1. Reduce the packaging speed or increase the voltage stabilizing device 2. Replace the high-power heating tube |

|

Packing bag seal leaks |

1. The temperature is not enough 2. Not enough pressure 3. The sealing time is too short 4. The front and rear horizontal sealing rollers are not sealed evenly 5. Clipping |

1. Increase the temperature appropriately 2. Check whether the total pressure is 6.5 kg 3. Increase the sealing time parameter appropriately 4. Carefully adjust the sealing parallelism of the horizontal sealing roller 5. Adjust the blanking time or inflation delay |

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us