- Home

- Product

- Volumetric Cup Filling

- High precsion small counting packing machine for candy capsule packaging machine manufacturer

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

High precsion small counting packing machine for candy capsule packaging machine manufacturer

- With the rapid development of science and technology, many things have been machined. The production of products such as "candies, medicines, seeds, health care products, and personal care industry" is no exception. What, how does the automatic counting machine work?

-

Counting tools are needed everywhere in production equipment. In packaging, a machine that counts grains is required, which can accurately count how many can be packed in a bag, and even find that the product is defective, and then screen out the defective product so that it does not enter the market. The automatic counting machine is small in size, light in weight, accurate in counting and easy to operate.

Counting packing machine component:

1) Main Packing Machine , 2) Counting Plate

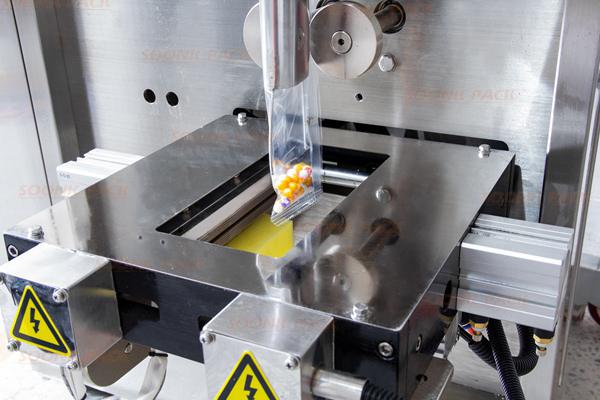

Some detailed pictures of counting packing machine:

Material storage device

Counting plate device

Date Printer device

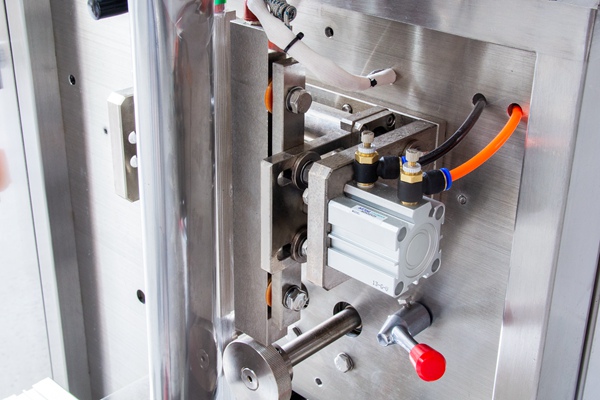

Vertical sealing device

The horizontal sealing device

Product Introduction

The counting machine is a new type of machine introduced by our company, which is a special counting machine for the pharmaceutical and confectionery industries. This machine adopts vibration effect, stable and reliable; scientific design, small size, light weight, low noise, accurate counting, simple operation, simple maintenance and repair. And the contact parts are made of stainless steel and plexiglass to ensure the cleanliness of the packaged items and meet the requirements of food and pharmaceuticals; this machine is currently the smallest, advanced, beautiful and economical counting bagging equipment among domestic counting machinery.

Scope of use

This machine is mainly used for the quantitative packaging of capsule preparations, pills, hard candy granules, etc. The counting is fast and accurate, and it can avoid direct contact with medicines, capsules and candy by human hands to ensure the hygiene of medicines and capsules. Suitable for small and medium batch production in hospitals, food, pharmaceutical factories, health care products factories, scientific research units, and laboratories. It can also be widely used as an ideal special equipment for counting, and bagging articles with regular shapes such as steel balls.

Structural characteristics of automatic counting machine :

Feeding device: The device is easy to operate, stable, reliable, easy to disassemble and assemble, and safe to use; The storage hopper is made of stainless steel and conveys materials in a sealed manner ; The quantity of products is accurate; It can reduce the labor intensity of workers and improve work efficiency.

Operating system: 1. Most of the machine configuration adopts famous foreign brands, such as PLC, etc., to ensure the smooth operation of the machine 2. When the machine fails, there is an automatic fault diagnosis and real-time monitoring alarm display system, and can store multiple sets of parameters, which can be called directly when the product is replaced.

Product Features

The counting machine is an improved product, which has improved the original vibration method, with lower noise and better vibration effect! The speed regulator of the counting disc is added to allow customers to adjust the speed according to their needs. The depth of the counting plate is increased, so that the hopper can put more raw materials, and the operator can conveniently observe and confirm the accuracy of counting! The bagging speed is fast, the fastest can reach 50 bags/min! 304 stainless steel is used, including the hopper and the bottom plate of the hopper are made of 304 stainless steel to ensure compliance with food and pharmaceutical requirements.

Operation process

1. Install the chassis of the counting plate, put the packaging film into the former, and install the power supply. 2. Put the candy or capsule material into the counting plate, turn on the power, and adjust the motor switch to the proper position, so that the holes in the counting plate will be filled in the required time.

Precautions

1. Capsules and candies, including other raw materials, must not work after being damp. 2. The counting plate must not be heavily pressed, otherwise it will not work properly; when lifting the machine, it cannot be lifted on the counting plate, otherwise the counting plate will become loose and damaged. 3. The diameter of the hole of the counting disc is determined according to the diameter of the material, and the diameter of the hole of the counting disc should be 2-3mm larger than the diameter of the material, and the thickness of the hole of the counting disc should be moderate, otherwise count the particles The chassis of the disc can be deformed. When the customer chooses the counting plate as the measurement method, it is best to send the materials and roll film to our company, and then our company will customize it. 4. This pellet counting plate is suitable for packing materials that are relatively hard and not easily deformed, otherwise the pellet counting plate will be crushed.

We put the material into the storage hopper, and vibrate the material to the counting plate through after vibration. The counting plate is accurately fed. The material must be filled with several particles, otherwise the accuracy is not high. Then the material is loaded into the packaging machine to obtain the packaging bag. The automatic measurement, bag sealing and date coding of the packaging process are realized.

Working principle: Put the materials into the upper hopper when working, and by appropriately adjusting the vibrating feeder, the materials accumulated in the hopper will gradually slide along the vibrating trough plate to the discharge port. Then the inclined vibrating plate is dropped one by one, and the material is dropped into the hole of the inclined vibrating plate one by one using the principle of photoelectric eye effect, and the counting function is realized through the cooperation of the circuit and the program.

The automatic counting machine is mainly suitable for the quantitative packaging of capsule preparations, hard capsules, pills, pills and other solid medicine granules, hard candy granules, etc. It is suitable for small and medium batch production in hospitals, food, pharmaceutical factories, health care products factories, scientific research units and laboratories. It can also be widely used as an ideal special equipment for counting and bagging of regular shapes.

Packaging type of the automatic counting machine: Three side sealing, that is, one side of the packaging bag is directly folded in half with the composite film, and the other three sides are heat-sealed. In fact, the three-side seal bag can be regarded as a supplement to the four-side seal bag. Compared with the four-side sealing bag, its advantage is that it can be expanded into a body bag after the bag is formed, and the space utilization rate is high. It is suitable for large-volume packaging needs and is often used for packaging cold granules and other products.

|

Product name |

SK-L3B320QD-A counting packaging machine |

|

Air consumption consumption |

0.65mpa,2.5m3/min.6kg/cm2 |

|

Packaging film width |

320mm |

|

Bag length |

50-200mm |

|

Bag width |

30-150mm |

|

Max outer diameter of coil |

Max.360mm |

|

Packing speed |

15-60bags/min |

|

Packaging film thickness |

0.04-0.08mm |

|

Power Specifications |

220V.50/60Hz.2.2Kw |

|

Dimensions |

(L)1050*(W)840*(H)1910mm |

|

Net weight |

260kg |

|

Gross Weight |

280kg |

|

Packaging materials |

Composite film |

Common after-sales Questions:

1.The leakage switch has tripped.

Reason: Leakage of heating element, motor and other electrical appliances.

Elimination method: check each electrical appliance one by one to eliminate leakage

2.The temperature is normal when the machine is shut down Reason: The ambient voltage is low, resulting in a reduction in the power of the heating element.

Elimination method: reduce packaging speed or increase regulated power supply

3.The sealing of the packaging bag leaks

Reason: The sealing ports of the front and rear horizontal sealing rollers are not parallel to each other; the temperature is not enough; the pressure is not enough

Elimination method: carefully adjust the parallelism of the horizontal sealing roller seal; appropriately increase the temperature; appropriately increase the pressure within the specified range

4 .Can't control cut point or half package.

Reasons: Wrinkles on the edges of the packaging film or quality problems in the light path cause the photoelectric to malfunction; the sensitivity of the photoelectric head is not adjusted properly; the paper puller is slipping; the electric brake gap is large or small or the oil enters;

Elimination method: replace the packaging film'; readjust the sensitivity of the photoelectric head; increase the spring tension of the pull-up wheel; adjust the electric brake gap to the specified size (or clean the oil stain); adjust the bag long wheel.

5.The sealing roller is not hot.

Reason: circuit breaker tripped; heating tube burned out; temperature control meter damaged .

Elimination method: check and eliminate the short circuit, reclose; replace the heating tube; replace the temperature control meter

5. The copper wheel does not move

Reason: The front electric brake cable is open; the AC contactor is in poor contact. Elimination method:: re-wiring; check the normally open contacts of the AC contactor, replace a set if necessary.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us