- Home

- Product

- Powder packing machine

- Wheat Powder packaging machine manufacturer

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

The wheat flour is packed in the video. The main machine of Soonkpack SK-L380DL type packaging machine is equipped with screw feeder + screw metering device + finished product conveyor combined scale vertical automatic starch packaging machine, starch is poured into the storage hopper of the screw feeder , Feed the material to the screw metering device through vibration and then weigh and pack it. After the packaging is completed, it will leave the packaging machine through the finished product conveyor to avoid the backlog at the bottom of the packaging machine and cause the packaging machine to stop.

Powder packing machine's companent:

1) Mian packing machine 2) Auger fille 3) Screw feeder 4) Finished bag conveyor

Some detaied pcitures of Wheat flour packing machine:

Auger filler system

Bag former system

Coding machine device

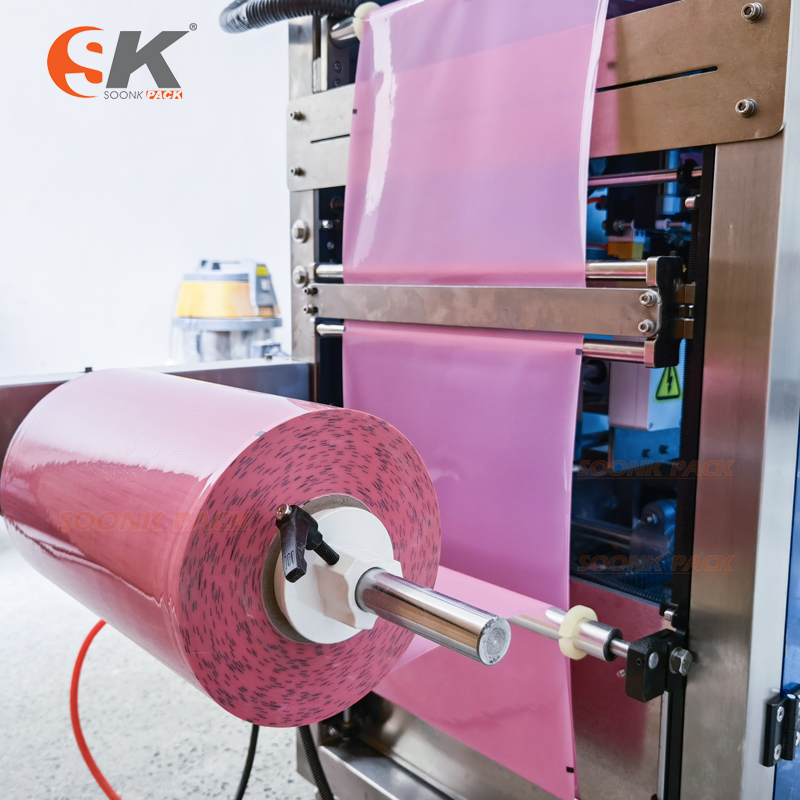

Film unwinding mechanism

Horizontal sealing device

Orderly electronic control box

Auger filler system: powder metering device is made of high-quality 304 stainless steel, with inclined screw metering device, which is accurate in weighing and measuring. The weighing and measuring speed is fast.

Bag former system: The bag former is made of stainless steel and has a long service life. The adjustment of the bag former can be adjusted through the touch screen, the operation is simple and convenient.

Coding machine device :Using automatic thermal coding instead of ink printing, it can print clear characters efficiently,20-120 times per minute,easy to use and convenient for maintenance.

Film unwinding mechanism: The external packaging film unwinding device is adopted, and the multi-link film reeling shaft coordinates the film transportation, and the film rolls more smoothly; the film conveying device adopts machining, and the details are processed accurately.

Horizontal sealing device: the horizontal sealing device of packaging machine has the same smooth surface treatment without hand stroke, and is equipped with fillet device.

Orderly electronic control box: the electronic control part of packaging machine is arranged neatly and orderly, and can quickly and effectively find relevant electronic control accessories in case of failure.

Introduction of powder packaging machine:

The automatic weighing powder packaging machine is to send the powder type materials directly into the spiral weighing silo through the screw elevator, and complete the automatic measurement, filling, automatic packaging and sealing, and finished product transportation according to the set weight.

Packaging machine features:

The screw metering machine is used to complete metering, filling, etc. It is suitable for metering powdery materials. It adopts a servo drive system and has the advantages of high precision and stable performance. The stainless steel open type material box is easy to clean, equipped with safety protection, and meets the corporate safety management requirements. Intelligent temperature control, accurate temperature control, to ensure that the seal is beautiful and smooth. Adopt PLC double-pull or single-pull film structure paper feeding system, the sealing and cutting position adopts the motor automatic correction device, the super large display touch screen constitutes the drive control core, which maximizes the control accuracy, reliability and intelligence of the whole machine; this machine and metering The configuration can automatically complete all the packaging processes of metering, feeding, bag filling, inflation (exhaust), and date printing, and automatically complete the counting; the perfect automatic alarm protection function minimizes the loss and helps to troubleshoot in time, packaging The styles of diversified, back seal, gusset, continuous bag, punching and so on.

Performance characteristics of flour vertical powder packaging machine:

1. The structure is compact, firm, simple to operate, easy to maintain, and occupy at least the ground;

1. Adopt PLC control, imported driver, imported touch screen, man-machine interface, high degree of automation, simple operation procedure, high sensitivity of touch screen;

3. The vibrating screw feeder can lift a variety of powder materials, and can be matched with the packaging machine to realize automatic feeding of material level tracking, or it can be used alone in other occasions;

4. The screw metering device is made of all stainless steel and meets the food hygiene certification. The filling adopts servo motor moving screw, which has the advantages of high precision, fast speed and long life. Fully sealed stainless steel composite material box, the material situation is clear at a glance. Easy to adjust, clean and maintain;

5. The finished product conveyor adopts belt conveying, which can be used alone or matched with the packaging machine to complete product conveying. It can choose material type, stainless steel, carbon steel spray structure, PVC belt stainless steel chain plate, PVC chain plate, etc.

6. Complete the production process of feeding, metering, filling and bag making, printing date, and product output automatically.

Notes on the operation of the powder packaging machine:

1. Set the parameters of each part according to the powder packaging machine manual to ensure the accuracy of packaging after the start of the operation.

2. In the packaging process of the powder packaging machine, the operation of each process must be carried out strictly according to the standard.

3. When the powder packaging machine is packing, if there is a leakage phenomenon, please do not put the weighing scale on the weighing platform, otherwise, the computer will think that the precise data of the one-time blanking has been adjusted to affect the accuracy of subsequent operations Sex and speed;

4. When foreign objects are found in the mouth of the material cup during the operation, the machine should be shut down and taken out. Note: Do not hold foreign objects with your hands before shutting down to avoid damage to the body caused by the rotation of the photoelectric spiral.

5. When replacing and cleaning the material cup screw, it is strictly prohibited to swing the screw horizontally to avoid breaking the screw slot in the next operation, which will affect the measurement accuracy of the screw and the material cup. When disassembling, it can be moved up and down to gradually disassemble. When the spiral is difficult to disassemble, the long shaft can be loosened to disassemble the spiral.

6. Do not place heavy objects on the sensor. The maximum load capacity shall not exceed the maximum weighing scale. Do not allow the sensor to be close to a larger seismic source, otherwise it will affect the accuracy of the sensor.

7. When changing the gasket, the powder packaging machine needs to pay attention to whether the thickness, direction and orientation of the two gaskets are appropriate. The bottom plate of the tension wheel must be narrow inward. The orientation of the gasket is best based on the orientation of the movable sprocket. Adjust its upper and lower positions.

How to use powder packaging machine

1. Before use, remove the two screws on the bottom plate.

2. After plugging in the power, turn on the switch on the side of the machine, check whether the computer control panel indicates whether the light is on and whether the machine emits a prompt sound, if yes, press the feeding button, and the equipment will be reset automatically Enter the standby state.

3. Pour the granular material into the bucket according to the demand, and then press the plus/minus key on the control panel to set the packing weight you need.

4. Select the desired speed on the degree control panel.

5. After the speed is selected, press the start button on the control panel, and the equipment will be fully automatic for automatic continuous quantitative dispensing.

6. At the beginning of the granule packaging, if you need to pause or the material has been filled, you can press the stop button and the equipment will enter the standby state.

Powder products with good fluidity, such as flour, starch, cocoa powder, coffee powder, milk tea powder, seasoning powder, cement powder, fertilizer powder, color master powder, metal powder, washing powder, chili powder, soybean powder, pepper powder , Cumin powder, etc.

Fully automatic packaging machine starch flour vertical powder packaging machine manufacturer packaging bag type.

|

Product name |

SK-L380FT Wheat Powder Packaging Machine |

|

Air consumption consumption |

0.65mpa,2.5m3/min. |

|

Packaging film width |

380 mm |

|

Bag length |

80-240 mm |

|

Bag width |

50-180 mm |

|

Max outer diameter of coil |

Max.360mm |

|

Packing speed |

10-55 bags/min |

|

Packaging film thickness |

0.04-0.08mm |

|

Power Specifications |

220V.50/60Hz.2.4 Kw |

|

Dimensions |

(L)1200*(W)820*(H)1350mm |

|

Net weight |

350 kg |

|

Gross Weight |

400 kg |

|

Packaging materials |

Composite film |

What is the reason that the screw feeder of the powder packaging machine does not work:

Powder powder packaging machine can be divided into small powder powder packaging machine, medium powder powder packaging machine and large powder powder packaging machine according to different sizes. No matter what kind of powder powder packaging machine, the function is to package powder powder products with good fluidity. , Such as flour, starch, baking powder, chili powder, facial mask powder, washing powder, color master powder and so on. It's just that the weight of the package is different.

If the powder packaging machine is fully automatic, it generally consists of four parts: screw feeder, screw metering device, packaging machine host and finished product conveyor. During the debugging process of the matched powder packaging machine or at the customer site, the screw feeder does not work, so what caused the powder powder packaging machine screw feeder not to work, today Songke company will organize it for everyone Click, as follows

1) Check whether the control function on the screen and on the electric box is turned on;

2) Check whether the control electric eye is damaged;

3) Check whether all the gearboxes are stuck due to lack of fuel, which leads to inability to work;

4) Check whether the motor is damaged or malfunctioning;

5) Check whether all wiring is normal;

The powder packaging machine is bought back to reduce costs and improve efficiency, but if the supporting screw feeder does not work due to misoperation, you can follow the above methods to troubleshoot and get solutions based on related problems.

Reasons for inaccurate material counting screw of vertical automatic powder packaging machine with leakage flap:

The vertical automatic powder packaging machine is mainly composed of four parts: the main machine of the packaging machine, the screw feeder, the powder metering device, and the finished product conveyor. The vertical automatic powder packaging machine mainly packs powder and powder materials, such as flour, starch, and coffee powder. , Soy milk powder, milk powder, Chinese medicine powder, washing powder, soybean powder, mung bean powder, etc. have better fluidity.

When the vertical automatic powder packaging machine is suitable for screw metering device, we aim at powder powder products with good fluidity. We need to install the bag leakage flap device on the screw metering device of the metering device. This can effectively prevent the powder powder from leaking during the packaging process, which may lead to the occurrence of packaging material clamping.

When the vertical automatic powder packaging machine is equipped with a leakage flap, what is the reason for the inaccurate material counting screw? Today, the editor of Songke will explain to you the reasons for the inaccuracy as follows:

1. Whether the screw measurement interval is too long;

2. Whether there is too much material, and the material is touched during the turning action;

3. Whether the flipping action is slow;

4. Whether the cutting speed is too fast or too slow.

5. Whether the servo motor control rotation position is normal.

6. The screw metering device has a pressurizing device.

7. Is the mixing function of the screw.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us