- Home

- Product

- Weigh Filling for Solids

- Double Vibration Plates Screw Counting Packing Machine

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

Double Vibration Plates Screw Counting Packing Machine

- The vibration plate of this machine is customized according to the size of the product. If you need this machine, you must order the material.

- The feature of this machine is that the automatic packaging machine adopts pneumatic structure, which makes the whole machine safer, stable and reliable. Unique packaging sealing technology makes the sealing beautiful and firm

Machine Component

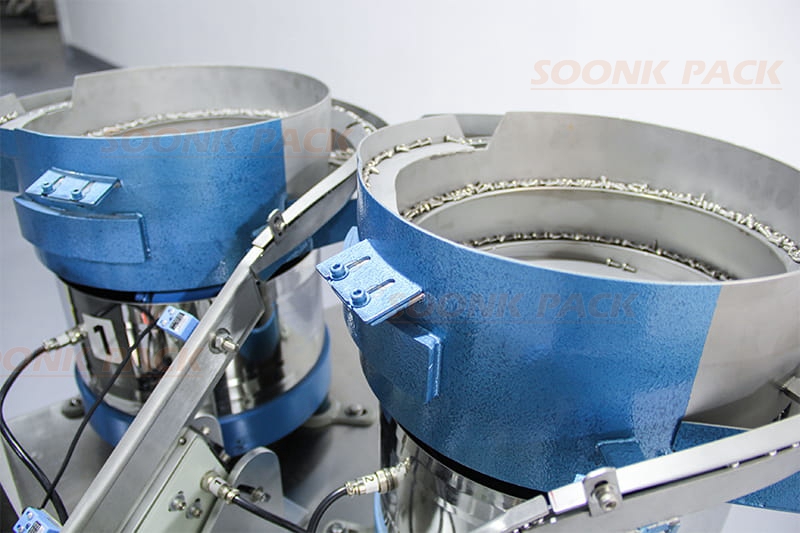

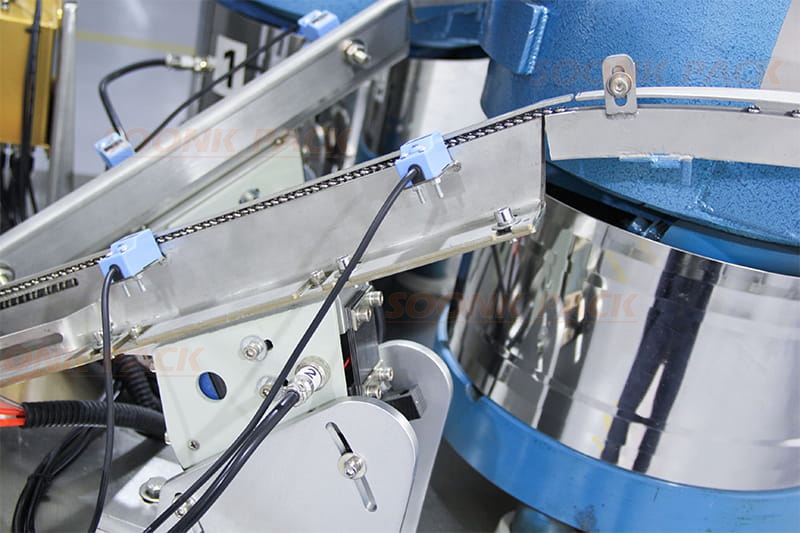

1) Main packing machine, 2) double vibration plates.

Main packing machine :Fully complete the production process of feeding, metering, filling, bag making, date printing and product output

Double vibration plate: The materials are placed on the vibration plate, and the materials are sorted in sequence through vibration, and then the points are counted. The double-vibration tray has fast packaging speed, improves work efficiency, and can also use two different materials.

Features of Double Vibration Plates

The vibration plate is customized according to the size and type of materials of customers.

The screws are put into the vibration plates, and the screws are sorted in sequence by vibration, and then counted by optical fiber. The corresponding screws are counted into the bag according to the number requirements setting, and then packaged into bags which are sealed and cut by high temperature.

Suitable for packaging a variety of hardware accessories products, such as hardware: combination of screws, nuts, gaskets, etc. Plastic parts: expansion tube, rubber ring, other accessories; Furniture accessories: self-tapping screws, fasteners, stamping parts, etc. Other accessories: bathroom hardware, electronic accessories, bicycle accessories, etc.

|

Model |

SK-L320-ZP |

|

Packaging Film |

Max 320mm |

|

Bag Length |

50-200mm |

|

Bag Width |

30-150mm |

|

Packing Film Roll Diameter |

Max.300mm |

|

Packaging Speed |

5-50bags/min |

|

Packing Thickness |

0.04-0.08mm |

|

Power Supply |

220V, 50Hz/60Hz, 2.8kW |

|

Measuring Range |

30-150ml |

|

Packing Material |

OPP/CPP/PE/PET |

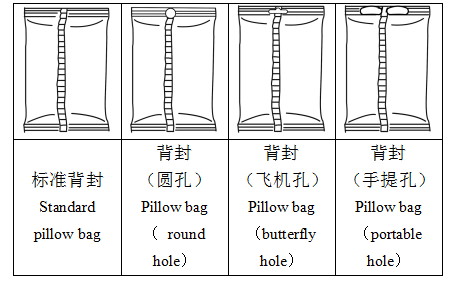

Standard pillow bag can be equipped with punching devices (butterfly holes, round holes, portable holes)

First of all, we must know the material, bag size and weight, these things are very important to the packaging machine. The designer will provide a schematic diagram and a salesperson to provide a quotation plan based on the customer's material, weight and bag size. For high-speed automatic twin packaging machine for food, the common questions from customers are as follows.

1. First of all, we must judge whether the material is suitable for the machine? It is best to send the materials and packaging film to our company for free testing. 2. Regarding the size of the bag, what should the customer do if there is no bag size? The suggestion is to experiment with local markets and supermarkets to see which bag type and the weight you want to pack are the most popular. The width of the bag is fixed because the length of the bag is adjustable. 3. Is the more shapers the better, so that more bag sizes can be packed? A set of machines can produce up to 3 formers, because the technology of replacing the formers is complicated, and changing the formers multiple times will result in the bag deviation. 4. What is the speed of this packaging machine? 10-160 packages per minute (depending on the material decision) 5. How to choose the material of the machine? Our machine has two materials, one is stainless steel and carbon steel. If you are pursuing high quality, choose stainless steel. If your financial budget is difficult, carbon steel is recommended. Although the appearance of the machine is carbon steel, the parts that come into contact with the material are made of stainless steel. 6. What is the error? Generally speaking, it is ±1% (depending on the characteristics of the material) 7. How many days does it take to produce a machine? The production time is about 30-45 days, because our machines are installed and debugged at the same time, so as to ensure high quality. 8. The customer also asked how long is the machine warranty period? We offer 12 months warranty, starts from the issue date of bill of loading and life time maintenance service. 9. Customers most often ask how to install and operate the video? You can't worry about this at all. Our company needs to provide user manuals, installation videos and operation of the machine, you can provide technical services when you encounter problems.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us