- Home

- Product

- Weigh Filling for Solids

- Fresh Noodle Vacuum Packing Machine

CONTACT US

SEND INQUIRY NOWTel: +86-757-81859859

Phone: +86-18902413057

Email: sales001@songkepack.com

Fresh Noodle Vacuum Packing Machine

- This machine is composed of a vacuum packaging main machine and an inclined bucket feeder.

- The biggest feature of this packaging machine is the vacuum packaging of noodles, which can keep fresh.

- This machine is specially designed for packaging fresh noodles, and its packaging bag is three-sided sealing, which caters to the market's demand for packaging fresh noodle bags.

Machine Component

1) Main packing machine,2) inclined bucket feeder, 3) output conveyor.

Main packing machine :Fully complete the production process of feeding, metering, filling, bag making, date printing and product output.

Inclined bucket feeder: The feeder can control the speed, which can raise the material to the main packing machine at a uniform speed, and is controlled by electric eye induction to ensure sufficient material.

Output conveyor :The finished product conveyor is installed at the product outlet of the main machine of the packaging machine, which allows the finished product to be transported away from the bottom of the main machine, avoiding product accumulation and blockage and causing downtime.

Machine Features

The packaging feature of this machine is vacuum packaging of fresh noodle.

The fresh noodle is manually put into the hopper of the feeding machine, and then the fresh noodle is transported to the packaging machine for vacuum packaging. The main packing bag type is the three side sealing bag type.

It is suitable for vacuum packaging of fresh noodle.

|

Model |

SK-L380 |

|

Air Consumption |

0.65mpa, 2.5m3/min |

|

Packaging Film |

120-380mm |

|

Bag Length |

80-240mm |

|

Bag Width |

50-180mm |

|

Packing Film Roll Diameter |

Max.300mm |

|

Packaging Speed |

5-85bags/min |

|

Packing Thickness |

0.04-0.08mm |

|

Power Supply |

220V, 50Hz/60Hz, 2.4kW |

|

Dimension |

(L)1200*(W)820*(H)1350mm |

|

Total Weight of Machine |

350kg |

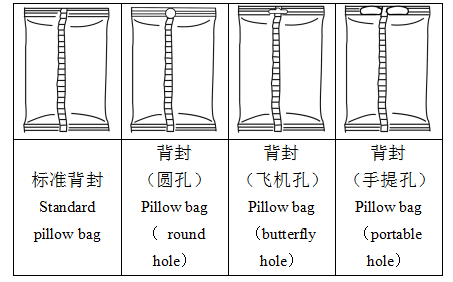

Standard pillow bag, and linking bags can be equipped with punching devices (butterfly holes, round holes, portable holes)

First of all, we must know the material, bag size and weight, these things are very important to the packaging machine. The designer will provide a schematic diagram and a salesperson to provide a quotation plan based on the customer's material, weight and bag size. Common questions from customers are as follows.

1. Regarding the size of the bag, what should the customer do if there is no bag size? The suggestion is to experiment with local markets and supermarkets to see which bag type and the weight you want to pack are the most popular. Only the width of the bag is fixed, because the length of the bag is adjustable.2. Is the more shapers better, so that more bag sizes can be packed? A set of machines can produce up to 3 formers, because the technology of replacing the formers is complicated, and changing the formers multiple times will cause the bag to have deviations.3. What is the error? Generally speaking, it is ±1% (depending on the characteristics of the material)4. How many days does it take to produce a machine? , The production time is about 30-40 days, because our machines are installed and debugged at the same time to ensure high quality.5. The customer also asked how long is the machine warranty period? We offer 12 months warranty, starts from the issue date of bill of loading and life time maintenance service.6. Most customers ask how to install and operate the video? You can't worry about this at all. Our company needs to provide user manuals, installation videos and operation of the machine, you can provide technical services when you encounter problems.

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us